Automatic Processing Automatic Processing

|

The Velopex Extra-X is very easy to use. Once switched on, the chemical is brought to working temperature

automatically. It is then only necessary to press the 'Run' button - and films can be posted through the entry slot in any order

and of any size. They are developed dry-to-dry in 4 minutes without further attention. After processing, the machine switches to

stand-by mode, maintaining the correct temperature for immediate further use.

Automatic x-ray processing avoids unnecessary re-takes - and therefore unwarranted x-ray exposure.

The Extra-X also saves valuable time, taking only seconds to load - and releasing staff to return to the chairside. |

Unique film transport system Unique film transport system

|

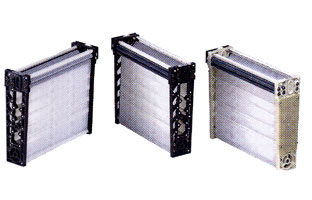

The key to Extra-X performance and efficiency is the unique Velopex film transport system in which x-ray

films are kept stationary and gently protected between two continuous permeable belts. Four identical modules carry the films

securely through the developer, fixer, water-wash and air-drying chambers.

This well-proven system virtually eliminates the risk of film loss compared with conventional multi-roller assemblies, and ensures

uniform exposure to the chemicals for consistently excellent results. |

Accepts All Film Sizes Accepts All Film Sizes

|

The Extra-X develops all sizes of x-ray film from intra-oral to panoral and full skull format. A

built-in guide is useful in organising small sized films. |

High Quality Radiographs, Fast High Quality Radiographs, Fast

|

Dry-to-dry radiographs of high quality are delivered in just four minutes, supporting the dentist's diagnosis while

the patient is still in the surgery. The Extra-X saves time and reduces patient recalls by making x-rays available promptly and conveniently -

and there is a 'fast lane' feature to produce endodontic film for viewing wet within two minutes.

After viewing the films may still be washed and dried if an archive record is required. |

|

Daylight or Darkroom Operation Daylight or Darkroom Operation

|

The Extra-X is supplied for daylight operation with a capacious and convenient daylight loader -

eliminating the need for a darkroom and the associated risk of film fogging. The loader can be fitted to the darkroom

version very simply at any time.

With the Extra-X, staff are no longer obliged to work with chemicals in a dark, confined space. |

|

Deep Processing Tanks Deep Processing Tanks

|

The deep chemical tanks provide for a long film path to allow generous film contact with the processing

solutions. The slim shape of the tanks keeps the surface area small, reducing the effects of chemical oxidation and evaporation. |

Compact and Easily Installed Compact and Easily Installed

|

Occupying little space the Extra-X is among the most compact automatic processors in its class. Installation

is very simple, and requires only a suitable power socket, cold water supply and water outlet. Simpler than plumbing in a domestic

washing machine. |

Minimal Maintenance Minimal Maintenance

|

Routine chemical replacement and cleaning are quick and straightforward. The machine is designed for

long life, maximum reliability and simple maintenance. The unique modular construction of the transport system ensures that,

in the unlikely event that a film transport module requires renewal, the module can be replaced in a matter of seconds at modest cost. |

Archivable Radiographs Archivable Radiographs

|

Films processed by the Velopex Extra-X form an accurate, permanent, non-corruptible record of treatment for

the future protection of both dentist and patient. |

|

|

Instruction |